Perpendicularity and flatness of hand planes

In order to work precisely, a hand plane should have a flat, i.e. straight sole. In addition, for planes that are also used for jointing, this sole should be at a right angle to the side walls of the plane body. In planing, "jointing" refers to the processing of board edges to create a right angle to the side of the board. This step is essential for clean gluing.

With the planes we sell, it often happens that both the flatness of the sole and the right angle to the sides of the plane are criticized as inadequate. In most cases, our inspection leads to the conclusion that the plane is fine. How do these discrepancies arise?

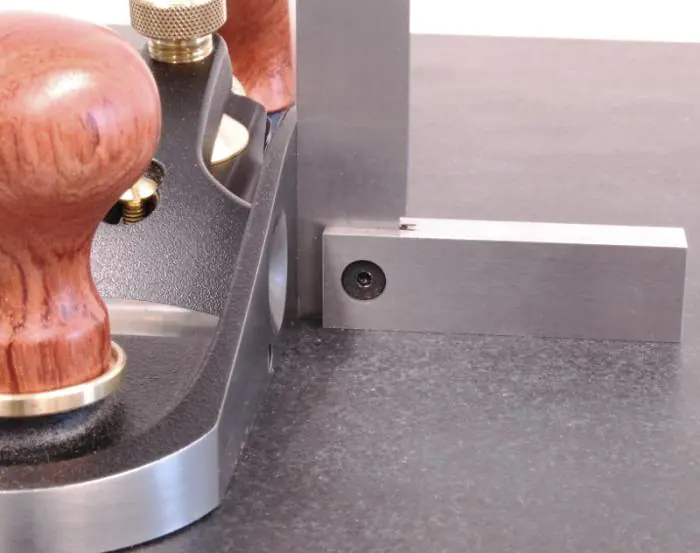

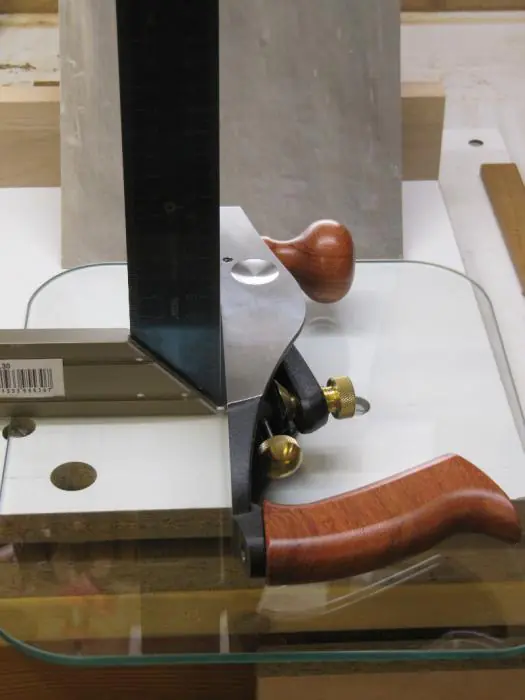

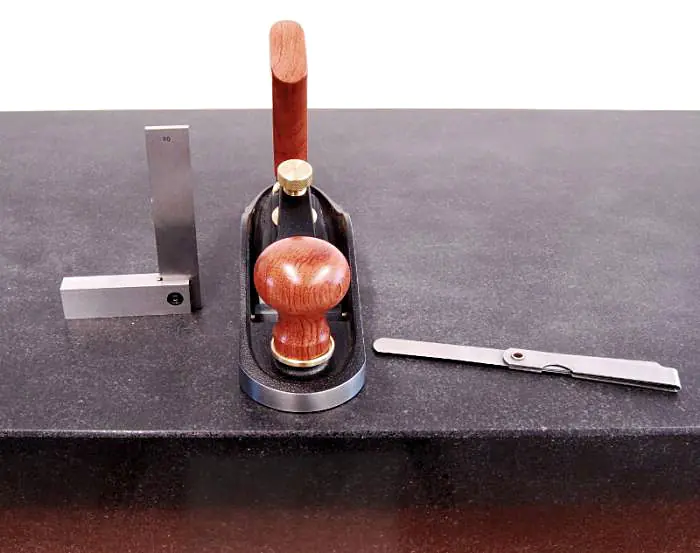

How we check the perpendicularity of the side to the sole and the flatness of the sole:

We use the following:

1. A calibrated, high-precision granite slab

2. A calibrated square with an accuracy of GG 0

3. A feeler gauge

This setup is the same as recommended and used by leading plane manufacturers. It is important that the sole of the plane itself cannot serve as a reference surface, but only as a neutral base, a kind of auxiliary reference point, which must be very precise. Particular attention must be paid to ensuring the surface is clean, as this can affect the result. A calibrated square (not a hair square) is then placed on the granite slab and brought close to the sides. If no gap is visible, the accuracy is perfect. If a gap is visible, a feeler gauge must be used at the open end of the gap. If a 0.002 inch (0.05 mm) feeler gauge does not fit between the two, the accuracy is within tolerance for manufacturers such as Veritas. If higher accuracy is desired—though far from practical for woodworking—it must be achieved by the user using standard lapping techniques. With Juuma planes, a 0.15 mm feeler gauge should not fit between the plane and the surface.

To measure the flatness of the sole, place the plane on the granite slab and attempt to insert a feeler gauge at various points. The tolerances are as described above (this applies to Veritas planes; a higher tolerance must be accepted for less expensive models).

Here are the measurement results for this plane: